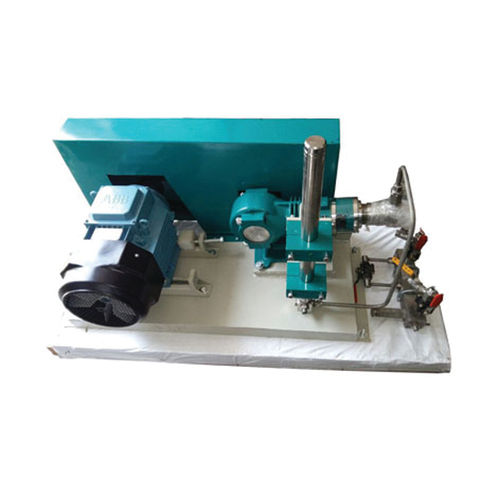

CO2 Production Plant

Product Details:

- Material SS

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Drive Type Electric

- Color White

- Warranty 1 Year

- Click to View more

X

CO2 Production Plant Price And Quantity

- 1 Piece

CO2 Production Plant Product Specifications

- Semi-Automatic

- PLC Control

- SS

- White

- Yes

- Electric

- 1 Year

CO2 Production Plant Trade Information

- Cash in Advance (CID)

- 10 Piece Per Month

- 1 - 4 Days

- All India

Product Description

We design a customized solution or a standard CO2 Production Plant. Plants that produce CO2 rely on burning kerosene, natural gas, and/or diesel fuel. A high CO2 concentration will be produced in the flue gas as a result of this complete and controlled fuel-burning process. The produced flue gas must first be cleaned and cooled in a scrubber or DCC with Caustic Soda Solution. The employment of a cold, chemical absorbent called "MEA" (Mono Ethanol Amine) in the subsequent stage only serves to recover CO2 from the flue gas, which is then liberated from the absorbent by the addition of heat and a stripping process. The MEA solution is recycled and circulated throughout the process. The emitted CO2 Gas will undergo several predetermined phases of compression, purification, drying, and liquefaction before becoming CO2 liquid. It has high efficiency of CO2 absorption with complete CO2 stripping. CO2 Production Plant is known for low fuel and utility consumption and is easy to install.

FAQs of CO2 Production Plant:

Q: What is the Automatic Grade of CO2 Production Plant?

A: The Automatic Grade of CO2 Production Plant is Semi-Automatic.Q: What is the Drive Type of CO2 Production Plant?

A: The Drive Type of CO2 Production Plant is Electric.Q: What is the Material used for CO2 Production Plant?

A: The Material used for CO2 Production Plant is SS (Stainless Steel).Q: What is the Warranty period for CO2 Production Plant?

A: The Warranty period for CO2 Production Plant is 1 Year.Q: What is the Control System used in CO2 Production Plant?

A: The Control System used in CO2 Production Plant is PLC (Programmable Logic Controller) Control.Q: Is CO2 Production Plant computerized?

A: Yes, CO2 Production Plant is computerized.Q: What is the Color of CO2 Production Plant?

A: The Color of CO2 Production Plant is White.Enter Buying Requirement Details

Other Products in 'CO2 Plant and Machinery' category

Super Cryogenic Systems Pvt. Ltd.

Noida, Uttar Pradesh, India

Noida, Uttar Pradesh, India

B No, C-18-19, Sector-8, Near Gautam Buddha Nagar, Noida - 201301, Uttar Pradesh, India

Phone :08045803940

|

SUPER CRYOGENIC SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese