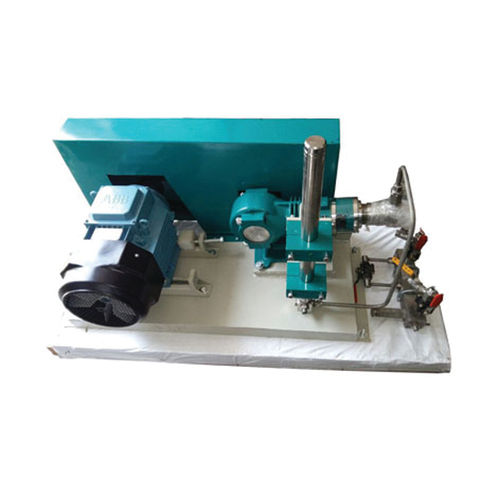

CO2 Recovery Plant

Product Details:

- Type CO2 Recovery Plant

- Material SS

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Drive Type Electric

- Color Black

- Click to View more

X

CO2 Recovery Plant Price And Quantity

- 1 Piece

CO2 Recovery Plant Product Specifications

- SS

- Yes

- CO2 Recovery Plant

- Semi-Automatic

- PLC Control

- Electric

- Black

- 1 Year

CO2 Recovery Plant Trade Information

- Cash in Advance (CID)

- 10 Piece Per Month

- 1 - 4 Days

- All India

Product Description

Our CO2 Recovery Plant is used in the production of High-Purity Carbon Di-Oxide. It is used in the beverage and food industries. The main purpose of these plants is to wash, purify, dry, liquefy, and store CO2 gas that is produced during the fermentation processes in breweries and distilleries, during the manufacturing of calcium chloride, and the creation of dry ice. It is designed for automatic operation and has low operating costs. This has a capacity of 50 Kg/hour to 4000 Kg/hour. It is manufactured with suitable material of construction to make food grade Carbon Di-Oxide. The production rate is 50 Kg/hour to 4000 Kg/hour which works with a voltage of 415/380 Volt AC/3PH/50 - 60 Hz. This super Cryo CO2 Recovery Plant can also be customized as per the requirement of the client.

FAQs of CO2 Recovery Plant:

Q: What type of material is used for the CO2 Recovery Plant?

A: The CO2 Recovery Plant is made of SS material.Q: Is the CO2 Recovery Plant computerized?

A: Yes, the CO2 Recovery Plant is computerized.Q: What is the warranty period of the CO2 Recovery Plant?

A: The CO2 Recovery Plant comes with a warranty period of 1 year.Q: What is the control system used in the CO2 Recovery Plant?

A: The CO2 Recovery Plant is equipped with a PLC Control system.Q: What is the color of the CO2 Recovery Plant?

A: The CO2 Recovery Plant comes in black color.Q: What is the automatic grade of the CO2 Recovery Plant?

A: The CO2 Recovery Plant has a semi-automatic grade.Q: What type of drive does the CO2 Recovery Plant have?

A: The CO2 Recovery Plant has an electric drive type.Enter Buying Requirement Details

Other Products in 'CO2 Plant and Machinery' category

Super Cryogenic Systems Pvt. Ltd.

Noida, Uttar Pradesh, India

Noida, Uttar Pradesh, India

B No, C-18-19, Sector-8, Near Gautam Buddha Nagar, Noida - 201301, Uttar Pradesh, India

Phone :08045803940

|

SUPER CRYOGENIC SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese